Doppleganger

Full Access Member

- Joined

- May 24, 2019

- Posts

- 12,677

- Reaction score

- 58,775

- Location

- OH-MI: Just like it sounds

- First Name

- Chris

- Truck Year

- 1985

- Truck Model

- K20

- Engine Size

- 5.7

Ok, without going into details as to how this occurred....here it is: I was going to run my compressor off my generator (still might but for a number of reasons wont if I dont have to) for 220 that my garage doesn't have. There is a generator receptacle on the side of the house that I use for back feeding the generator and running the house when the power goes out. I had an idea of how to run my compressor off of that receptacle from the house. I wired a 220 plug in the garage with a twist lock receptacle, so that instead of plugging the extension cord into the generator to back feed the house, I plugged it into the plug in the garage and got 220 FROM the house. Neighbor down the street does this with a welder.

So I try it out and it seems to run fine, except after about 10 min the compressor motor (I think) wants to stall, so I turn it off immediately. Trying it again with a meter (it will run fine for about 5-10 min) it shows the power at the motor drops from 220v to about 200v. My guess is the 10ga wire run (100-120ft) is too long for the amp draw of a 5 HP compressor. NEMA shows 150ft as doable for stoves, heaters, etc but never mentions an air compressor.

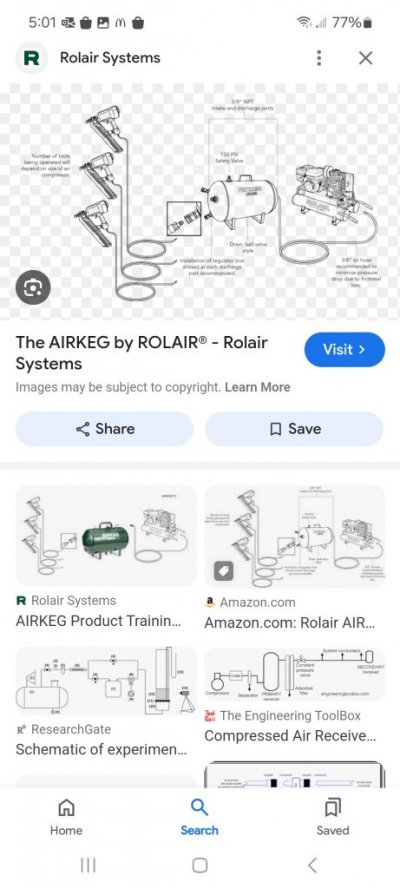

Plan B thought: I have a 30 gal compressor that is 110v, half as loud and works great. Was thinking of plumbing it into my 80 gal tank and pressurizing it with the the 30gal compressor. Or, maybe just using the 80 gal as a storage tank for the 30?

Just thinking out loud - was hoping someone who had BTDT would chime in. I need to get my cab into primer and am running out of time and ideas. Heck, just the 30gal might be fine for that.

Thx

So I try it out and it seems to run fine, except after about 10 min the compressor motor (I think) wants to stall, so I turn it off immediately. Trying it again with a meter (it will run fine for about 5-10 min) it shows the power at the motor drops from 220v to about 200v. My guess is the 10ga wire run (100-120ft) is too long for the amp draw of a 5 HP compressor. NEMA shows 150ft as doable for stoves, heaters, etc but never mentions an air compressor.

Plan B thought: I have a 30 gal compressor that is 110v, half as loud and works great. Was thinking of plumbing it into my 80 gal tank and pressurizing it with the the 30gal compressor. Or, maybe just using the 80 gal as a storage tank for the 30?

Just thinking out loud - was hoping someone who had BTDT would chime in. I need to get my cab into primer and am running out of time and ideas. Heck, just the 30gal might be fine for that.

Thx