Mr Stay Puft

Member

- Joined

- Jan 6, 2022

- Posts

- 45

- Reaction score

- 69

- Location

- California

- First Name

- John

- Truck Year

- 1989

- Truck Model

- V1500 Suburban

- Engine Size

- 350 TBI

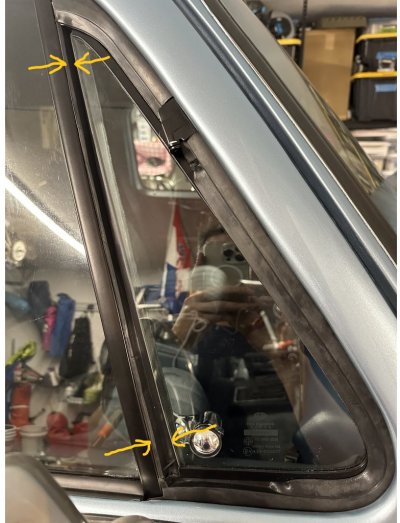

I just got my vent windows back from Precision who did a full rebuild on both. I was hoping it was going to fix the wind noise I was having around them, but it seems actually worse. I’ve attached a video and some pictures. The seal at the top is not adequate. I’m getting a ton of noise through it. I know, blare the stereo…. Is there an adjustment I am missing? It almost looks like the entire window needs to be rotated clockwise. I am not getting enough of a seal at the top and it looks like the bottom has a ton. Also if you look at the back edge of the glass it isn’t parallel to the metal dividing support between the main window and vent window.

xc_hide_links_from_guests_guests_error_hide_media