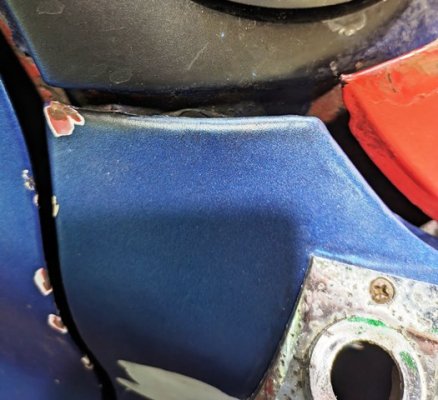

Keep in mind good panel fit at GM was a suggestion. Compared to today's vehicles it was horrible. Have to bend, shim, and accept lesser of the evils. No 2 panels were ever the same. Fenders are wider in back shims need to come out. A pry bar will work to modify the rear upper fender corner. That would be less noticeable than a bad hood fit.

Any offshore parts........... good luck.

Here's how we did it:

"Quote=Keith Seymore

What we used to do for fender shims is tape a packet together, like 3 shims, and we would run those all day whether the truck we were currently building needed it or not.

Eventually the final repair supervisor would call back and say something encouraging, like "SEYMORE!! YOU IDIOT!!

WTH ARE YOU THINKING?!?! ALL THESE FENDERS ARE RUNNING HIGH!! ARE YOU EVEN

LOOKING AT THESE TRUCKS?!? TAKE A SHIM OUT BEFORE I COME BACK THERE AND SHOW YOU HOW TO DO THIS!!" I can just imagine the spittle flying into the phone mouthpiece.

So we would start running a new shim pack, like 2 shims, until he called again with his latest observation.

Basically it was to address "macro trends". You had about 45 seconds to complete the truck in front of you and move to the next one; that's not enough time to fit and re-fit each individual truck."

Also -

"This technique would get you close on the majority of vehicles.

There was a repair station at the end of my area. There was also a short moving repair line (two, actually) at the end of final line. If they could fix them there while on the move then they would; otherwise it would be out to a stationary repair stall in "heavy repair" for the really bad ones.

I should add that some of the repairs did not consist of removing the bolt or adding/deleting shims. Often the repair consisted of bending, twisting or hammering while the line was moving."

K