mattsk8

Full Access Member

- Joined

- Jun 5, 2024

- Posts

- 172

- Reaction score

- 448

- Location

- Michigan

- First Name

- Matt

- Truck Year

- 1986

- Truck Model

- K20

- Engine Size

- 350

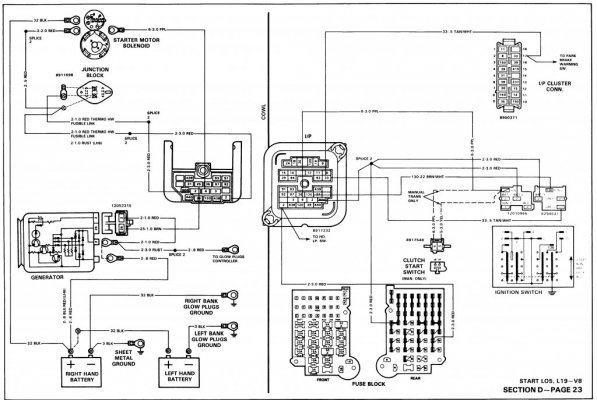

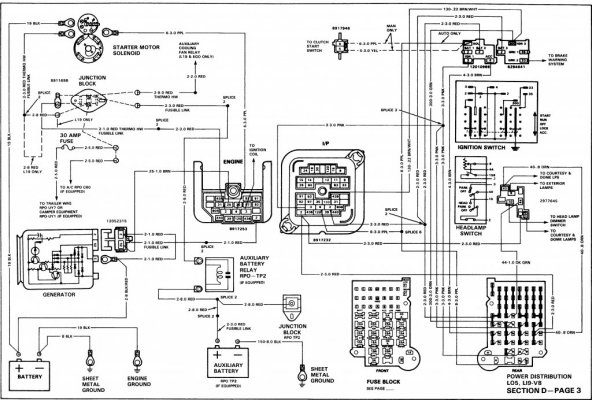

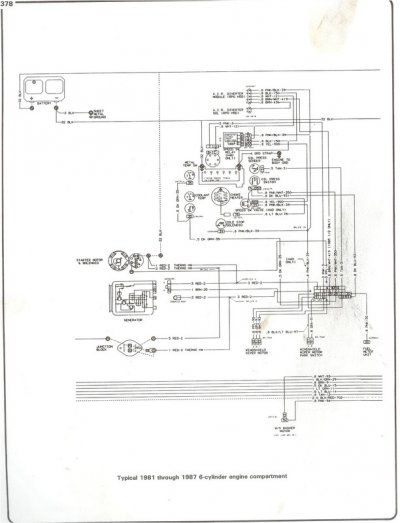

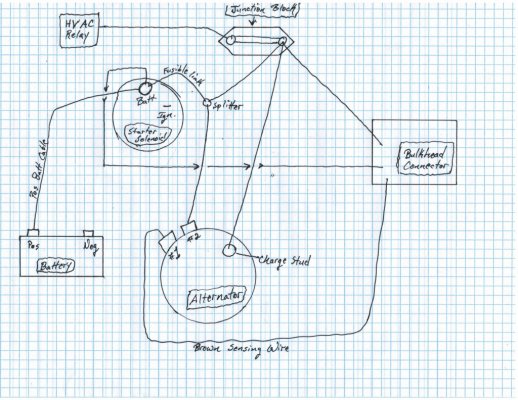

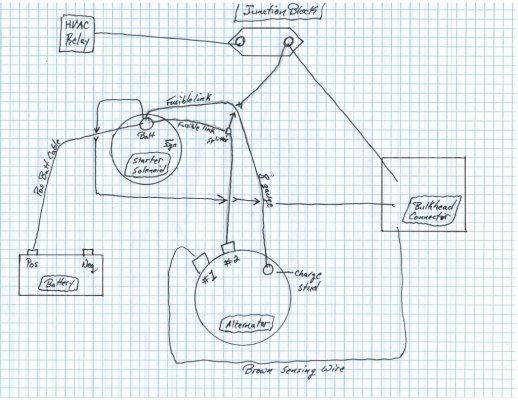

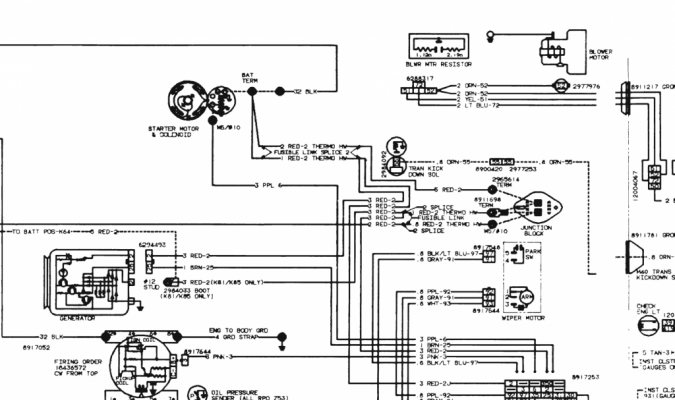

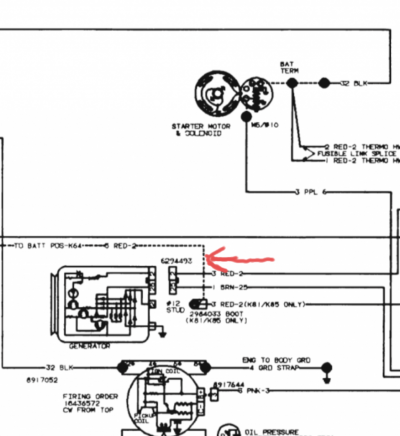

I've researched this a lot and still can't find sense to why GM wired this the way they did. On my 1986, it's wired this way...

Battery to starter... Starter via fusible link, then split to 2 wires going to alternator spade 2, other wire to the bulkhead plug on the firewall... Starter via fusible link to junction block (junction block feeds HVAC relay, and another red going to the bulkhead plug)... and this is the wire that confuses me- alternator stud to junction block.

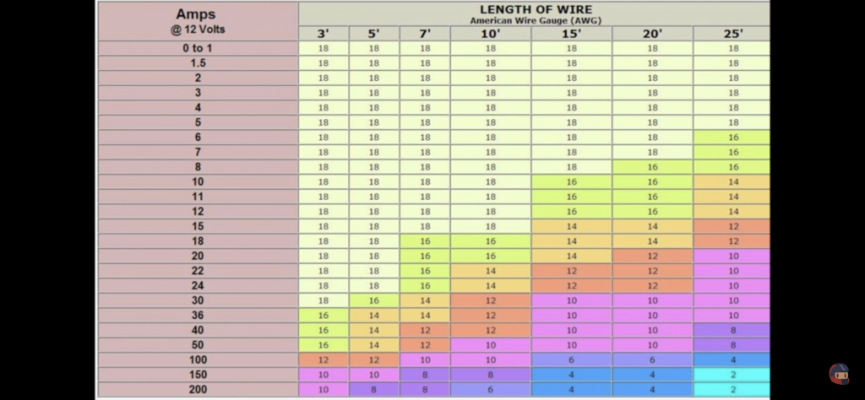

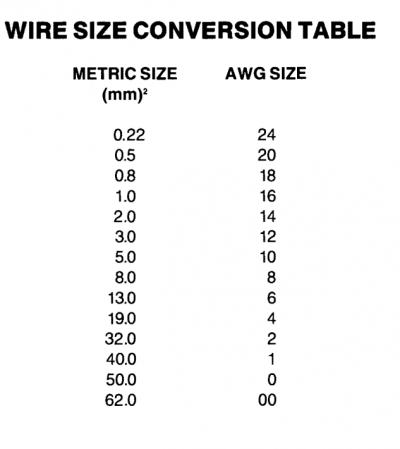

Why wouldn't GM have instead ran this charge wire to the battery stud on the starter? It would've been a shorter run. I'm asking because I'm rewiring my alternator with an 8 gauge, and I'm going to pull the wire that used to go from the alternator charge stud to the junction block out and instead go from the charge stud on the alternator to the battery terminal on the alternator. Is there any reason not to do this?? That junction already has the 12 gauge red feed from the batt terminal on the starter, I don't see why I would run the alternator charge wire all the way to that rather than going to the starter.

Thanks for any input and sorry if this is confusing. I can draw a picture if that would help. I have a schematic, and I've researched this a lot and haven't come up with an answer to my question. It just seems like going from the alternator charge stud straight to the batt wire on the starter (or even straight to the positive batt terminal) makes a lot more sense.

Battery to starter... Starter via fusible link, then split to 2 wires going to alternator spade 2, other wire to the bulkhead plug on the firewall... Starter via fusible link to junction block (junction block feeds HVAC relay, and another red going to the bulkhead plug)... and this is the wire that confuses me- alternator stud to junction block.

Why wouldn't GM have instead ran this charge wire to the battery stud on the starter? It would've been a shorter run. I'm asking because I'm rewiring my alternator with an 8 gauge, and I'm going to pull the wire that used to go from the alternator charge stud to the junction block out and instead go from the charge stud on the alternator to the battery terminal on the alternator. Is there any reason not to do this?? That junction already has the 12 gauge red feed from the batt terminal on the starter, I don't see why I would run the alternator charge wire all the way to that rather than going to the starter.

Thanks for any input and sorry if this is confusing. I can draw a picture if that would help. I have a schematic, and I've researched this a lot and haven't come up with an answer to my question. It just seems like going from the alternator charge stud straight to the batt wire on the starter (or even straight to the positive batt terminal) makes a lot more sense.