It does not have to be factory spec to get good points for a clean resto-mod.

If your ground strap or loom mounts to the 3/8" short bolt to the back of the head, remove it once, bleed while doing so and NEVER EVER mount anything there again. (Unless you enjoy bleeding to get it out again and again).

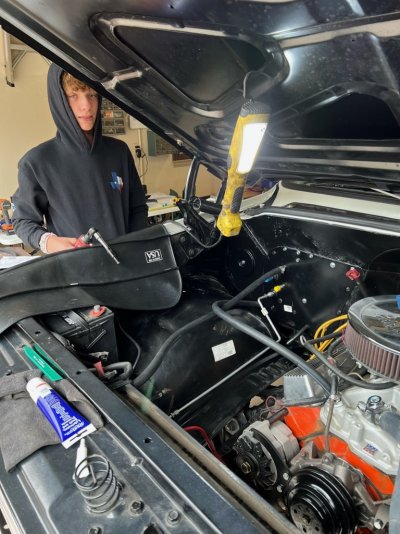

Extend those wires and clean the routing up. Buy some quality heat shrink able CRIMP connectors, buy the correct Ideal Crimper tool and re-rout everything like the C10 Cream Colored truck picture. Try to find a donor harness from a bone yard to keep the sensor wires the correct color codes, or invest in a Painless Harness and bite the bullet for a complete solution.

There are much better locations and sturdier distribution blocks for a safe electrical system. The 2 stud plastic junction block is a dud.

These trucks are meant to be worked on. Make it easy to work on in the future.

Do not tape it to death, a couple wraps every few inches keeps it clean and allows you to get back into the loom, when you need to. If you bury a crimp connection, your screwed.

GM originally mounted this stoopid stuff or wrapped wires through areas prone to exhaust heat exposure.

That cream truck is not my engine bay, however mine is on the forum for you to search for using my sig. It's not a show truck, because I use it for Mountain roads for fire wood and Hunting. My harness looks very similar, though, with substantial upgrades everywhere. My firewall has a 600 amp distribution block, from SkyCraft, in Orlando.

My threads related to electrical and fuel systems upgrades, tools and methods of protecting your systems via fly back, using relays, diodes, resistors and Zener diodes.

I recommend upgrading every ground and battery wire 2 sizes, if you can afford to do so. If your truck has a 10 gauge wire to the alternator, go 8 or 6. (I had 4 laying around).

Battery to starter: 2 gauge.

Fat battery wires rule when you eliminate the ability for corrosion to occur, because of sub standard wire gauge.

The "headlight relay mod", with properly fused relays, with fly back, oversized 12 gauge headlight harness, new connectors and piggies everywhere. Then bundle up your excellent crimps, using the tools I have recommended and wrap it for show or at least to keep the dirt out. Then the PowerMaster 150 or 200A alternator will run like a top and you can adjust for the AGM or Lithium battery upgrades, without improperly charging you modern battery selection.

Hit up my profile and search the electrical related posts, for my tech threads.

I list a lot of really good tools that are not very expensive and work.

Not every post will relate to your 86', but a lot of it will upgrade your electrical for reliability in a modern word. Build it slowly, as your budget allows.

You might save a few bucks on poorly performing tools and resolve some of your wiring issues, as you find them, upgrading everything.

The OEM electrical system for the 80's trucks is severely lacking.

The 16ga wires are all intentionally under rated for the expected service life 5 years max. They get corroded, kill all the electrical components, until your mechanic freaks you out with a service and repair bill equal to the cost of a new car payment.

The cool thing is, after you rewire everything the way you want it, you'll know every circuit like the back of your hand. Just buy quality connectors and use pigtails unless you have $150 for every Weatherpack and Delphi crimper rated for safe road use.

If you have the cash, or restoring your harness upsets you, go Painless Performance and get it over with. Just request they upgrade the wiring gauge for the entire harness, when you order. If you use the tools I recommend in my threads you can do this on a budget and succeed.

How old is your truck, with 5 year rated OEM wiring?