hey mister

Full Access Member

- Joined

- Jun 15, 2024

- Posts

- 335

- Reaction score

- 723

- Location

- North Coast

- First Name

- Marty

- Truck Year

- 1978

- Truck Model

- C10

- Engine Size

- 350

78 Big 10.

When I got this truck, my son-in-law enlightened me as to how easy it is to punch out these ignition switches. Then nothing more than a large flat blade screwdriver is used as the key.

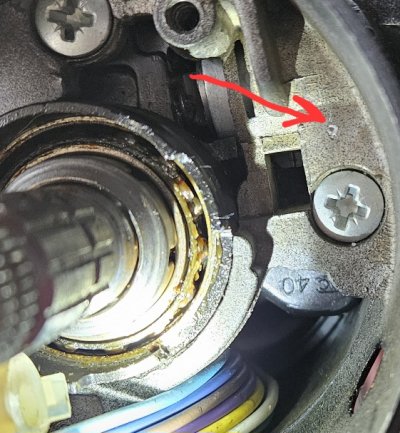

Well buggers! That just won't do. I need at least a few seconds to rack a round. So a new ignition switch was ordered. Borrowed the steering wheel puller and dove in. In the manuals it showed some models with a cross bolt to make the said "switch punching" a bit more of a challenge. Perfect. This might be the few seconds we be lookin' for.

The nice thing is the steering column is a die cast allow. (i.e. easy to drill and tap)

After packing gauze in all the possible nooks and crannys for chips to hide in, a precise guess-timated location of the cross bolt was selected and center punched and the drilling commenced, followed by a vigerous tapping. Then the shop vac cleaned up.

The cylinder came with a notch so the cross bolt could pass thru. I used a long 10-24 set screw as the cross bolt and dabbed the threads with clear fingernail polish to keep it in place, yet removable if need be.

Now they may still be able to gut the switch, but the flat blade screw driver is useless and the steering wheel lock pin can not be accessed. That's all the time I need.

When I got this truck, my son-in-law enlightened me as to how easy it is to punch out these ignition switches. Then nothing more than a large flat blade screwdriver is used as the key.

Well buggers! That just won't do. I need at least a few seconds to rack a round. So a new ignition switch was ordered. Borrowed the steering wheel puller and dove in. In the manuals it showed some models with a cross bolt to make the said "switch punching" a bit more of a challenge. Perfect. This might be the few seconds we be lookin' for.

The nice thing is the steering column is a die cast allow. (i.e. easy to drill and tap)

After packing gauze in all the possible nooks and crannys for chips to hide in, a precise guess-timated location of the cross bolt was selected and center punched and the drilling commenced, followed by a vigerous tapping. Then the shop vac cleaned up.

The cylinder came with a notch so the cross bolt could pass thru. I used a long 10-24 set screw as the cross bolt and dabbed the threads with clear fingernail polish to keep it in place, yet removable if need be.

Now they may still be able to gut the switch, but the flat blade screw driver is useless and the steering wheel lock pin can not be accessed. That's all the time I need.