skysurfer

Full Access Member

- Joined

- Oct 23, 2010

- Posts

- 2,676

- Reaction score

- 2,164

- Location

- west coast

- First Name

- John

- Truck Year

- 1989 Suburban

- Truck Model

- V2500

- Engine Size

- 5.7/TH400/NP241C

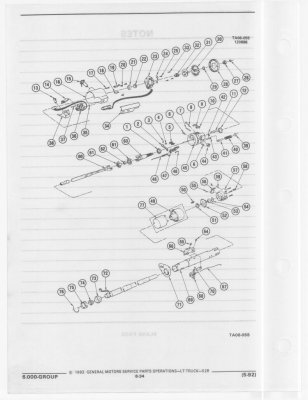

Done deal and everything works. The other end of that toothed slide below the black cam has to be hooked on a pin in the lower part of the steering column, I missed that and also part of the spring has to stick into the large hole in the black piece.

I found it necessary to unhook the wires at the base of the column. There was no way to get the signal switch and housing out of the way without more slack.

The white connector sits at 6 0'clock and is easy to get to. I had to remove the two bolts holding the metal bracket and drop it down a bit so I could reach the black connector which sits at 3 o'clock on the column. Note the white high beam switch peeking out from 7 o'clock.

Having the panel removed from the lower dash comes in handy when you're doing the reassemby since the high-beam rod falls out of the switch every five seconds.

I like to do things on-the-cheap and MacGyver my way through things but this is one job I'm glad I bought the right tools before starting. The locking plate compressor and pivot pin remover got plenty of use and were worth every penny.

I found it necessary to unhook the wires at the base of the column. There was no way to get the signal switch and housing out of the way without more slack.

You must be registered for see images attach

The white connector sits at 6 0'clock and is easy to get to. I had to remove the two bolts holding the metal bracket and drop it down a bit so I could reach the black connector which sits at 3 o'clock on the column. Note the white high beam switch peeking out from 7 o'clock.

Having the panel removed from the lower dash comes in handy when you're doing the reassemby since the high-beam rod falls out of the switch every five seconds.

You must be registered for see images attach

I like to do things on-the-cheap and MacGyver my way through things but this is one job I'm glad I bought the right tools before starting. The locking plate compressor and pivot pin remover got plenty of use and were worth every penny.