Cj1234

Junior Member

- Joined

- Mar 8, 2025

- Posts

- 4

- Reaction score

- 1

- Location

- Orange County

- First Name

- CJ

- Truck Year

- 1978

- Truck Model

- c10

- Engine Size

- 5.7 350 sbc

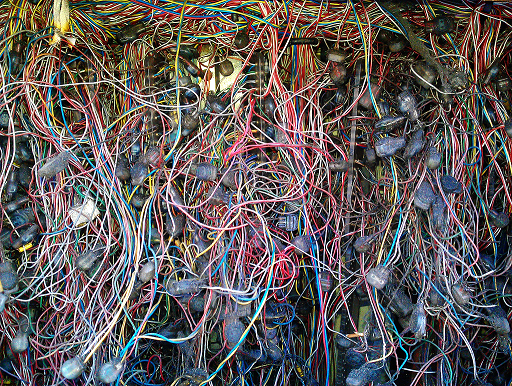

This is a sloppy wiring job I know but this is how I bought the truck (1978 Chevy C10). What’s the best way to fix/clean this up without having a million wires going to both terminals? After sitting for 2 weeks it seems to pull and drain power from the battery causing it to die often. I’m assuming it’s the absolute mess on my terminals so, how should I go about this!

You must be registered for see images attach

until I corrected everything. But I fear this is just the tip of the iceberg. You really need to see where those wires are going...you might just find out that some, if not all, are even needed!

until I corrected everything. But I fear this is just the tip of the iceberg. You really need to see where those wires are going...you might just find out that some, if not all, are even needed!

![20250414_112912[1].jpg](/data/attachments/386/386645-b9215db960bd5409ad10b505b02341db.jpg)