One thing, to get the choke to fully close. The throttle needs to be opened fully.

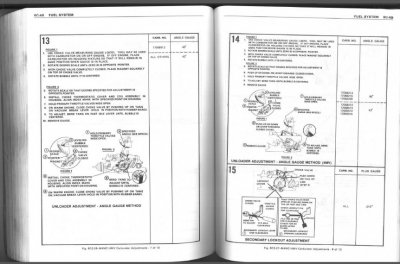

Check Your cable/linkage to be sure that the plates are fully opening, with the pedal to the metal.

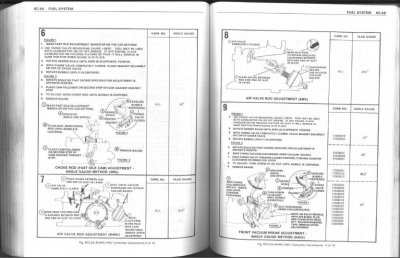

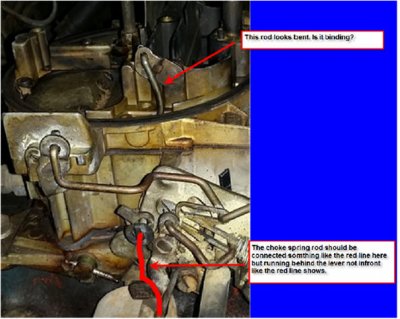

The reason that the zip tie was on there was to keep the fast idle cam from operating, also, the linkage rod, going to the choke pull off has been bent to keep the choke from closing. When the engine is started, the choke pull off should be adjusted so that, it will pull open the choke but, not pull it open so far that it lens out the fuel/air mix so much that the engine dies when it is cold.

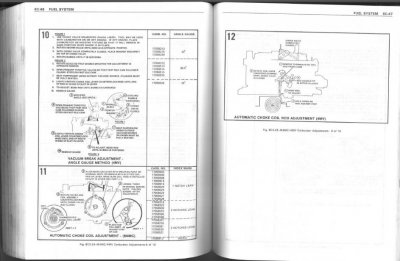

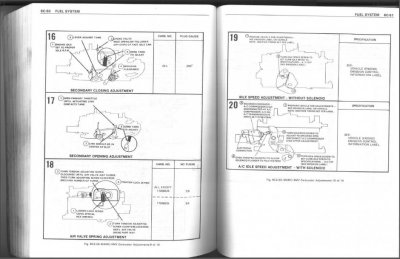

Get a vacuum pump, attach it to the choke pull off, vacuum up the diaphragm, it should hold, now, with vacuum applied, slight pressure on choke plat, towards the closed position, adjust the rod, by bending it, so that the choke is open about 3/8ths of an inch open. The book gives degrees of angle but, most people have no angle gauge so I adjust the pull off to 3/8ths then, after the engine is started and running, make My final adjustments from there. Just not so far closed that the engine lopes and, not so far open that the engine dies.

Someone did`nt know any thing about adjusting the Q jet carbs and so, they jerry rigged it so that the choke would not work at all.

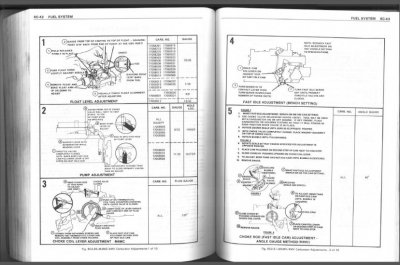

Just remember, before making any adjustments to the choke, be sure to full open the throttle then, close the choke plate then, release the throttle while holding the choke plate shut. By doing this, it will also set the fast idle cam, read the instructions/specs for which step of the cam the fast idle adjuster screw should be setting on.

Good luck, I think You will get it all figured out and have a great running pigumup.