Been doing some brake work on my truck recently. Had some issues last season and recently replaced all the hardware, shoes and cylinders on the rear wheels. Also replaced the master cylinder and the two lines to each wheel since the old lines where so stuck in the cylinders I had to grind them off.

Bled all the brakes and everything seemed fine. Jacked up the rear end and pushed the brake pedal - no rear brakes at all. I can spin the wheels by hand. Front brakes work good and parking brake works. I adjusted the shoes outwards as much as i could, but that ended up with one rear wheel overheating, and still no braking power. Now im not sure if I ever had rear brakes the 3 years i`ve had the truck….

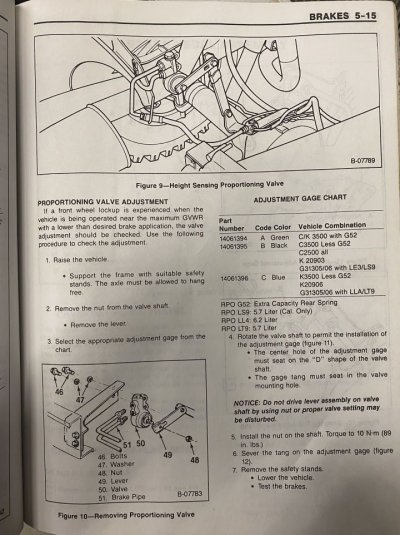

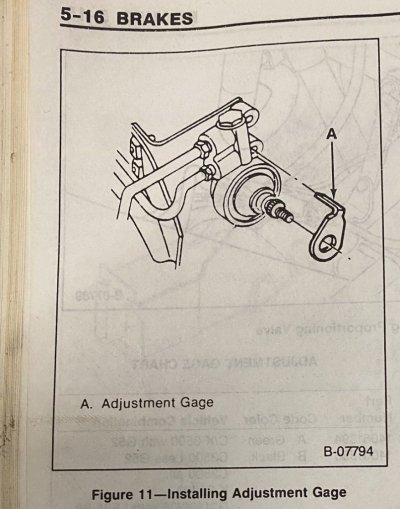

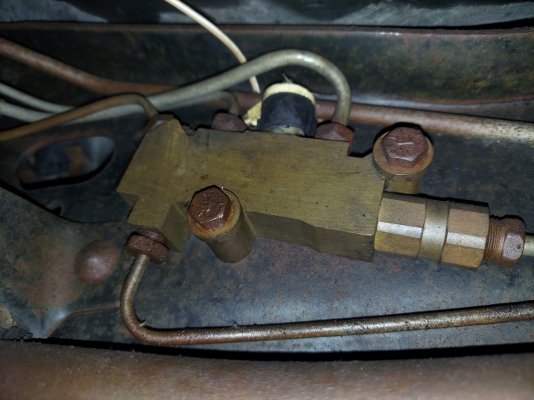

My suspision is towards the proportioning valve in the front or the load sensing valve in the rear.

Grounded out the cable on the proportioning valve and that gave me the brake warning light, so at least the wiring from there is good. If the valve has been out of position i should have got the warning light - if the valve is in good condiotion that is. How normal is it for these to go bad?

The placement is horrible and virtually impossible to inspect without removing it.

Too many chances of snapping a line, so not keen on removing it if one cannot with a fair amount of certainty say its defect. How is the little connector on top removed?

Disconnected the lever at the LSV and tried moving the little switch all different positions, but no changes. I can hear and feel some sort of piston inside moving when i spin it around.

Put wd-40 on all the connections but i can just feel everyone of them not coming easily off. Already startet rounding off one nut at the LSV.

Would like to snap as few as possible

Any tips for a poor guy?