randomTruckKid

Full Access Member

- Joined

- Feb 26, 2024

- Posts

- 215

- Reaction score

- 157

- Location

- Rockport tx

- First Name

- Brian

- Truck Year

- 79

- Truck Model

- C10

- Engine Size

- 350

They're just grade 8 bolts that were the same size/length as what we cut off.When you say bolt, are you using the correct stud, which I believe is serrated or are you using just a Grade 8 off the shelf?

There are washer/ spacers that go on before you shim but I feel like they are about 1/4". Something is definitely wrong if you are having to put 1" of shims in. If the springs are cut, I could see you having to put a lot of shims in though.

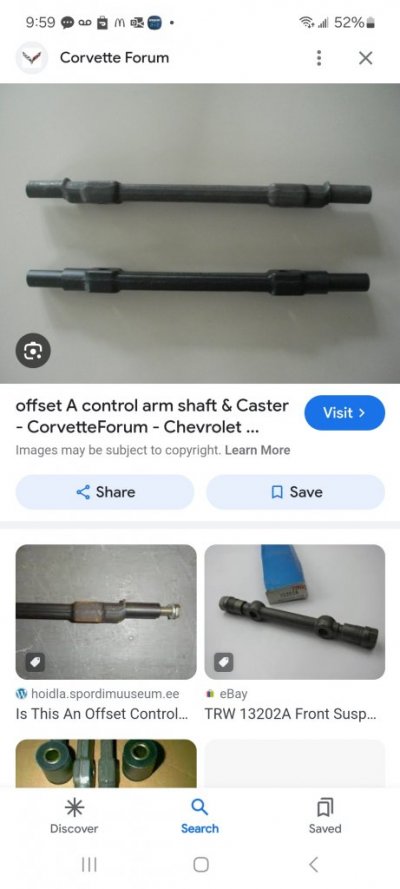

Also some shafts are offset so turning 180 might get you closer.

I'm still confused as to why you are putting C20 arms in on a C10?

You must be registered for see images attach

You must be registered for see images attach

We are lifting the truck it was previously lowered 3 in. But I was really suppried when I still had to put quite a few shims in.

You must be registered for see images attach

then the other side.

Also the c20 control arms were advertised as c10 ones. They must just be people modifying c20 arms to fit c10 ball joints.