chengny

Full Access Member

- Joined

- Feb 22, 2012

- Posts

- 4,084

- Reaction score

- 1,029

- Location

- NH

- First Name

- Jerry

- Truck Year

- 1986

- Truck Model

- K3500

- Engine Size

- 350/5.7

From a previous post in this thread:

I'm having a hell of a time getting air exchanger removed. Can't get to the lower nuts in the engine compartment, and the top stud is spinning. Of course I don't have any help to hold the stud with some vise grips on the other side if that would even work. This isn't going to be fun. I"m thinking of drilling access holes in the inner fender well to get to the lower bolts.

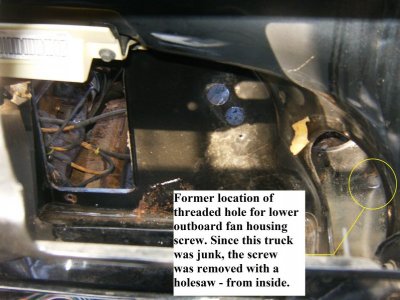

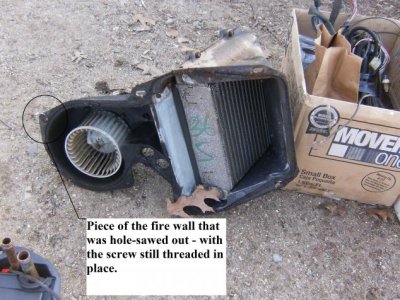

Here is a trick to release the hardest screw to reach - the lower outboard one that holds the blower housing. It is the same on both non-A/C and A/C setups. Remove the blower from the housing and reach down into the vestibule. Move your fingers out toward the fender and you will feel the pointy end (and about 3/4" of the threads) of that screw where they have penetrated the firewall.

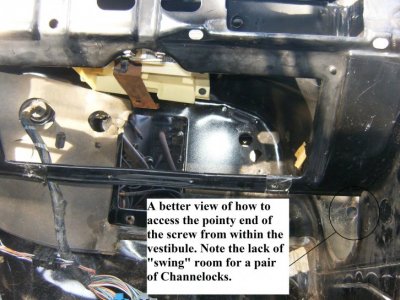

Using a small pair of Channelocks, grip the threads and turn the bollt CW (as if tightening). You won't be able to see it, but the head of the screw will start backing off from the blower housing flange. Keep taking little half-turns with the pliers as long as you have something to grip.

You won't be able to turn the screw all the way out from inside the vestibule with your hand down inside - you'll eventually run out of threads to grab. But at some point you can pull the fan housing far enough away from the firewall to allow access to the screw between the housing and firewall. Finish turning it out with a pair of needle nose pliers.

It goes slow due to the lack of room to work in. You only get maybe a 1/4 of a turn each time you re-grip the threads and throw the wrench/pliers - then the handle hits the wall and you have to go back and get a new grip.

Another way you can try is to remove the kickplate and fresh air inlet damper. The end of that bolt will be visible where it penetrates the firewall. It is easy to see and easy to reach into the vestibule but the fact that it is pointing straight at you makes it difficult to turn.

Some visual aids:

I'm having a hell of a time getting air exchanger removed. Can't get to the lower nuts in the engine compartment, and the top stud is spinning. Of course I don't have any help to hold the stud with some vise grips on the other side if that would even work. This isn't going to be fun. I"m thinking of drilling access holes in the inner fender well to get to the lower bolts.

Here is a trick to release the hardest screw to reach - the lower outboard one that holds the blower housing. It is the same on both non-A/C and A/C setups. Remove the blower from the housing and reach down into the vestibule. Move your fingers out toward the fender and you will feel the pointy end (and about 3/4" of the threads) of that screw where they have penetrated the firewall.

Using a small pair of Channelocks, grip the threads and turn the bollt CW (as if tightening). You won't be able to see it, but the head of the screw will start backing off from the blower housing flange. Keep taking little half-turns with the pliers as long as you have something to grip.

You won't be able to turn the screw all the way out from inside the vestibule with your hand down inside - you'll eventually run out of threads to grab. But at some point you can pull the fan housing far enough away from the firewall to allow access to the screw between the housing and firewall. Finish turning it out with a pair of needle nose pliers.

It goes slow due to the lack of room to work in. You only get maybe a 1/4 of a turn each time you re-grip the threads and throw the wrench/pliers - then the handle hits the wall and you have to go back and get a new grip.

Another way you can try is to remove the kickplate and fresh air inlet damper. The end of that bolt will be visible where it penetrates the firewall. It is easy to see and easy to reach into the vestibule but the fact that it is pointing straight at you makes it difficult to turn.

Some visual aids: