1low4x4

Full Access Member

- Joined

- Feb 14, 2011

- Posts

- 2,409

- Reaction score

- 716

- Location

- Texas

- First Name

- Nick

- Truck Year

- 1984

- Truck Model

- K10

- Engine Size

- 5.7

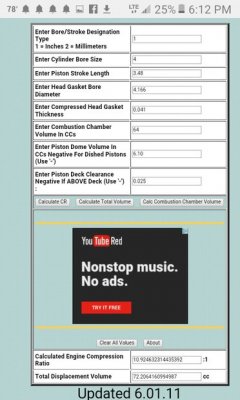

So, Last time I called Comp cams, they wouldn't or couldn't recommend a cam to me, even with all my engine specs, without a compression ratio. My guess is they don't really know without the computer telling them, and the computer requires a compression ratio. So..

I looked up a compression calculator and then searched for the numbers Id need. Everything was pretty straight forward until the "Deck Clearance". Is there a way to measure this with the head on?

For deck clearance, I found 0.025 as a good number for a stock 350, but I have flat top pistons with 4 valve relief, so Im not sure if that changes the number. At any rate, I plugged in these numbers and this is what I came up with. basically 11:1 compression. It sounds high, for what the engine is, but Im not sure.

The engine is just a stock bore and stroke (4.00-3.48) 350, with 64 cc vortec heads, The dome volume number of +6.10 was pulled from the sheet on the pistons I bought, the compressed gasket of .041 was also pulled from the literature provided with the gasket.

Anybody tried this before?

I looked up a compression calculator and then searched for the numbers Id need. Everything was pretty straight forward until the "Deck Clearance". Is there a way to measure this with the head on?

For deck clearance, I found 0.025 as a good number for a stock 350, but I have flat top pistons with 4 valve relief, so Im not sure if that changes the number. At any rate, I plugged in these numbers and this is what I came up with. basically 11:1 compression. It sounds high, for what the engine is, but Im not sure.

The engine is just a stock bore and stroke (4.00-3.48) 350, with 64 cc vortec heads, The dome volume number of +6.10 was pulled from the sheet on the pistons I bought, the compressed gasket of .041 was also pulled from the literature provided with the gasket.

Anybody tried this before?

Attachments

Last edited: