91 Jimmy

Junior Member

- Joined

- Nov 2, 2020

- Posts

- 9

- Reaction score

- 0

- Location

- Central Mass

- First Name

- Rich

- Truck Year

- 1989

- Truck Model

- 3500

- Engine Size

- 454

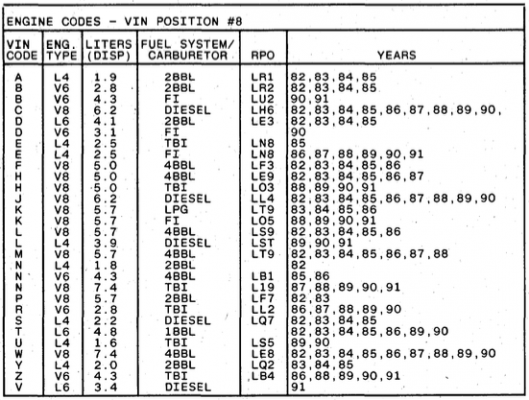

OK, that's what I thought. Now for the next question; here is a side by side of the oil pressure sensor (or switch, I'm not sure what the difference is?) I bought from Rockauto vs. the one that was on the old engine:You don't need #3 if your vehicle is now carbureted and running a mechanical fuel pump. That oil pressure/fuel pump switch is required with an electric fuel pump in the event of a crash and subsequent loss of oil pressure when the engine dies, it opens the circuit to the fuel pump so it shuts off and doesn't keep pumping fuel up to the engine and start/feed a potential fire. When you turn the key on with the original system, or any modern vehicle for that matter, you hear the fuel pump kick on for a few seconds and shut off, and then when you crank the engine and it fires up and the system/sensor/switch sees oil pressure it closes the circuit so the fuel pump will run while the engine is running. No oil pressure at that location= no electric fuel pump.

You must be registered for see images attach

The new one is a little longer, but they both have the same thread which brings me to the following question: The thread on the Tee is larger than the thread on either the new or old oil pressure sensor so I can't thread it directly into the block. So, do I use the tee but plug the other end if I don't need number 3 in the schematic above as QBuff02 mentions?

You must be registered for see images attach