....

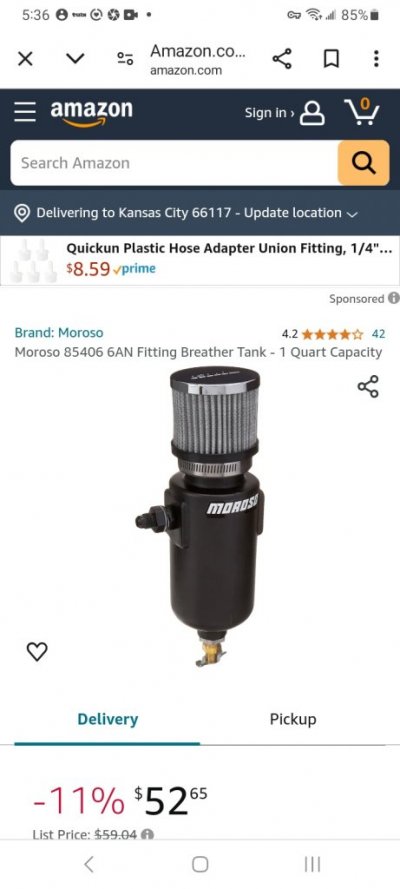

Spoke too soon. I was feeling good about the truck so I drove it to work on a Friday a week or two ago. Everything was good on the way into work. But on the way home at every stoplight I was getting a small oil smoke cloud. Made it home thankfully but when I looked in the hood the oil dipstick was out of the tube a little bit and I had oil on the inner fender and all down the underside of the passenger side of the truck. This was somewhat disappointing but life goes on. Anyway, I got back to it last night and ran a compression test and it looks like cylinder 3 has found something better to do.

So now what? I have a few options that I can think of. The first is to redo the rings and main bearings. I have never had an engine that far apart before and I am willing to try. But I wonder is that my best option? It could be a bent or stuck valve, and then I'd have to look into redoing or replacing the heads and all those parts.

No matter what I think I'll have to pull the head(s) off and look at them but again I've never torn an engine apart that far and I'm worried I'll miss something.

You must be registered for see images attach