Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 6,285

- Reaction score

- 10,674

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

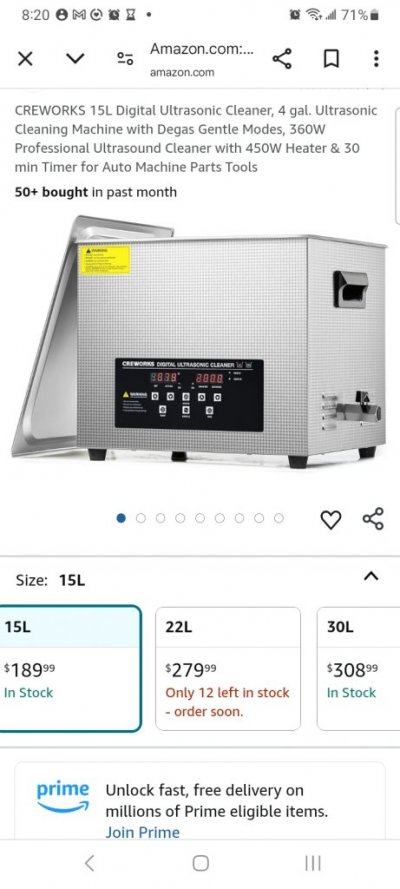

I just bought a fairly big ultrasonic cleaner. I heard they are the latest and greatest for cleaning carbureator bodies for rebuilds. I've read you should never allow parts or baskets to touch the sides or bottom of the pan.I've read that best results are when your parts are in the middle of the solution. I've also read to preheat my cleaning solution instead of letting the unit bring it to temp. So here's what I'm thinking, lay 2 wood slats over the top of the pan opening and use all thread with double nuts top and bottom to hang the carbureators in the center,side to side and top to bottom,second Idea was hang with fishing line from wood slats. Planning on using 50/50 pinesol and water. Thoughts?advice?

Last edited: