Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 6,406

- Reaction score

- 10,916

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

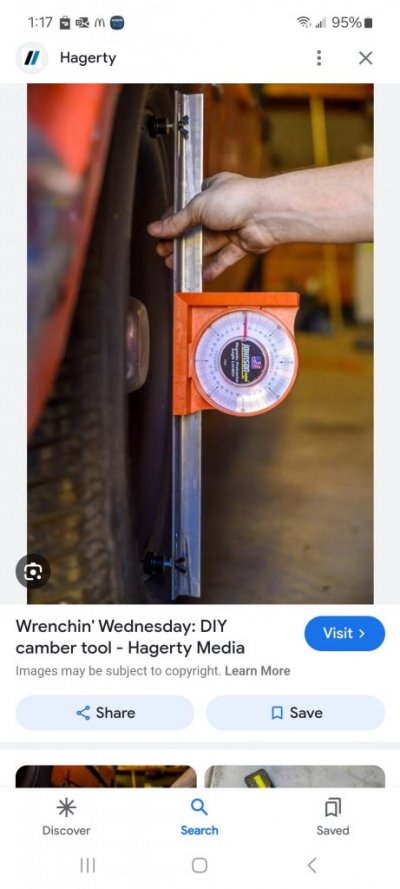

Okay took a quick skim through^^^^ park the front wheels on sand,trash bags,a magazine etc. To reduce friction, cut your conduit a couple of feet longer than your approximate outside to outside track width. Drill four holes 2 in each conduit approximately 1 foot wider than your outside track width. Both conduits should have the holes the same distance apart this keeps your string parallel. Raise or lower the jack stands to get the string close to the middle of the axle. Measure left front center of axle to string, then right front. Move conduit side to side until your measurements are equal. Do the same in the rear double check,front and rear. Now with the wheels pointed straight ahead measure string to front edge of wheel,then rear edge of wheel. The difference is toe in or toe out. In the front check side to side moving your steering wheel until you have equal readings on both sides. Rear check front of wheel,rear of wheel and compare readings if left wheel forward reading is 1/4 closer to the string left rear reading is 1/4 inch further from the string,rightfront is 1/4 further right rear is 1/4 further etc. You know the rear is shifted. Caster and camber can be check with an angle finder app on your phone. More later. Gotta go.

Last edited: