Toad455

Full Access Member

- Joined

- Aug 3, 2023

- Posts

- 152

- Reaction score

- 107

- Location

- North Texas

- First Name

- Kevin

- Truck Year

- 1978

- Truck Model

- C10

- Engine Size

- 6.0

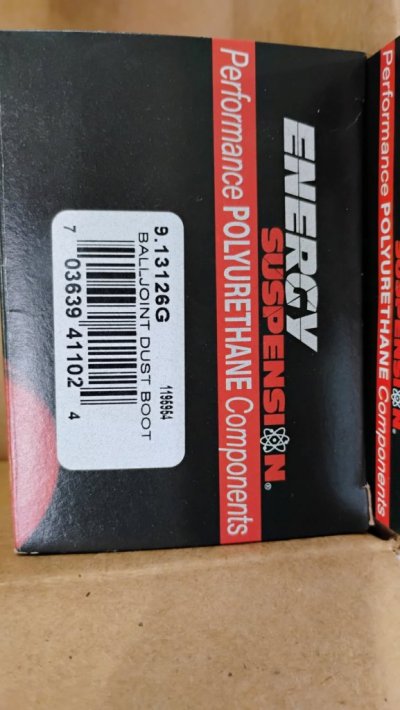

Hello. I'm finally getting my controls arms finished after blast, paint, bushings, and I just pressed the lower ball joints in and the grease boot slips up after I press them down. This is on a 78 C10. Ball joints are Moog K6117T. Before I complain or blame Moog I'm wondering what I can be doing wrong. The joints are pressed all the way in. I used a collar that came in the C-Clamp kit that fits nice over the rubber boot. I used the clamp to press the ring of the boot all the way down but when I release the clamp it slips up about 1/8" and you can see the splines on the ball joint, they just won't stay down. The ball joint hole on the top of the control arm is tapered so there not enough flat surface on the ball joint to grip the boot. I can press the boot down by hand to mimic the spindle assy sitting on it and it does not go all the way down. Has anyone had this issue or have any ideas. I don't want to run it like this and have grease come out all around the bottom. I attached some pics, thanks.