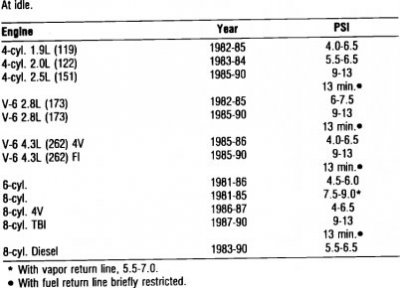

To check system leak down rates you need to somehow temporarily restrict the flow through the return line. The shop manual uses the term "briefly" which is misleading - they mean the entire time the leak down is being checked. See the table at the bottom; your 12 lbs is well within range. But unless you block the return line you will not get an acceptable pressure retention time.

The most critical and truest evaluation of the system is the fuel flow rate. They don't come right out and say it but if you get your beer can full of gas in 15 seconds (or less) you can stop testing the fuel system - you are good.

FUEL PUMP FLOW TEST

1.Disconnect the EFI fuel feed line, then connect suitable hose to line and direct end into suitable container.

2.Apply battery voltage to the fuel pump test terminal. The fuel pump should supply 1/2 pint or more fuel within 15 seconds.

3.If fuel flow is below minimum, check for fuel restrictions. If there is no restrictions, check pump vacuum and/or pressure.

FUEL PRESSURE TEST

- Turn engine "OFF" and perform Fuel Pressure Relief procedure.

CAUTION: A small amount of fuel may be released, after the fuel line is disconnected. In order to reduce the chance of personal injury, cover the fitting to be disconnected with a shop cloth. Place the cloth in an approved container when disconnect is completed.

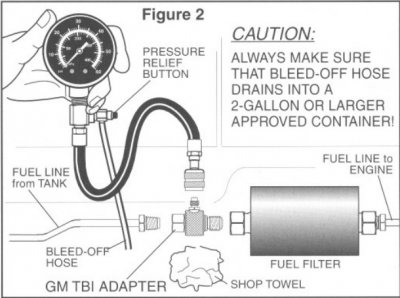

- Install fuel pressure gage J-29658A/BT8205, or equivalent, at the outlet side of the in-line fuel filter.

- Start engine and observe fuel pressure reading. It should be 62-90 kPa (9-13 psi).

- Relieve fuel pressure.

- Remove fuel pressure gage.

- Re-install fuel hose or pipe assembly to in-line fuel filter.

- Start engine and check for fuel leaks.

*** THIS PROCEDURE HAS BEEN UPDATED BY TSB # 90-6C-89, Dated 9/90

Some 1985-90 engines equipped with 2.5L, 2.8L, 4.3L, 5.0L, 5.7L or 7.4L may experience a condition where fuel delivery is interrupted to the engine causing a "no start condition". This condition may be caused by deterioration of the in-tank fuel pump coupler hose located between the fuel pump sending unit and the fuel pump. This condition may be repaired by replacing the original coupler hose with a new VITON coupler hose kit P/N 25028041. The kit consist of a new VITON hose and two clamps.

Pressure, Vacuum and Temperature Specifications: