Ricko1966

Full Access Member

- Joined

- Apr 11, 2017

- Posts

- 5,390

- Reaction score

- 8,598

- Location

- kansas

- First Name

- Rick

- Truck Year

- 1975

- Truck Model

- c20

- Engine Size

- 350

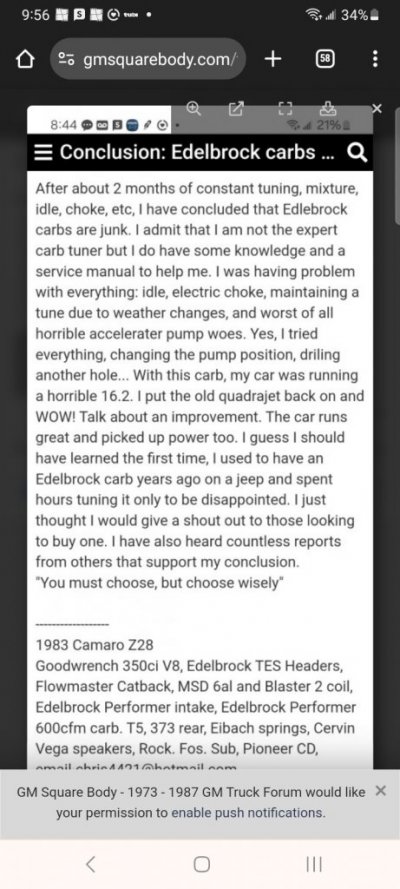

Okay I was on 3rd gen the other day and there was a guy on there, he pulled his factory Qjet, replaced it with a new Edelbrock went to the strip and lost almost a full second. I don't remember his build I'll find it and post it. Anyway pulled his Edelbrock back off and went back to his Qjet. He didn't jet it,didn't try to dial it in,it didn't outperform what he took off so he put things back like they were. I've helped out more than one member who put in a generic distributor,then started thinking they needed to dial in the carb. Like this guy,he thought the carb needed help. I told him to change the distributor curve 1st. Not bagging on him just an example

(Wow, went to the lightest springs and what a difference. Super peppy thru all throttle ranges now. Thanks Ricko!) Because the distributor wasn't right for what he needed out if the box.

Here's the deal, the guy that lost a second he only knew that because he ran it at the strip, he didn't know it just driving around,if he had jetted it and dialed it in for his combo he probably would have got his time back,and maybe more. The point is when you put in/put on a generic 1 size fits all,big block,small block,auto,manual,stone stock, big cam,different heads etc etc. it fits everything. This one size fits all stuff will do all of this,but probably not well or as well as it could,unless you dial it in for YOUR engine not every single engine ever made. A lot of times people spend money and it's the placebo affect I spent x dollars and it runs so much better now,it maybe slower,you don't know unless you check it.Anyways people if you are going to put on generic parts, to get the most out of them you need to dial them in. No way can a manufacturer make one part that will work optimal on everything right out of the box. That's why GM had hundreds of carbureator setups and Distributor curves. Read his post,there's more to carbureators than,mixture and choke. A lot more. And there's a lot more to distributors than setting timing.

(Wow, went to the lightest springs and what a difference. Super peppy thru all throttle ranges now. Thanks Ricko!) Because the distributor wasn't right for what he needed out if the box.

Here's the deal, the guy that lost a second he only knew that because he ran it at the strip, he didn't know it just driving around,if he had jetted it and dialed it in for his combo he probably would have got his time back,and maybe more. The point is when you put in/put on a generic 1 size fits all,big block,small block,auto,manual,stone stock, big cam,different heads etc etc. it fits everything. This one size fits all stuff will do all of this,but probably not well or as well as it could,unless you dial it in for YOUR engine not every single engine ever made. A lot of times people spend money and it's the placebo affect I spent x dollars and it runs so much better now,it maybe slower,you don't know unless you check it.Anyways people if you are going to put on generic parts, to get the most out of them you need to dial them in. No way can a manufacturer make one part that will work optimal on everything right out of the box. That's why GM had hundreds of carbureator setups and Distributor curves. Read his post,there's more to carbureators than,mixture and choke. A lot more. And there's a lot more to distributors than setting timing.

Attachments

Last edited: