Almost forgot the mention the fun I had before leaving on Friday. I needed to swap in the factory driveline, change the alternator belt, check/set the timing, and get the wire ran to the temperature sending unit, and then clean off the transmission and load up. Sounds easy enough right?

Went to install the factory driveline I got out of the parts truck and had a new bearing installed on Wednesday. It is two solid shafts, and the only slider is into the tranny. I couldn't get it to slide in the tranny. Fought with it for a good 30 minutes before it finally bottomed out in the tranny. With this driveline design it eleiminates all of the slop the rear slider that the PO had in there. On the factory driveline there is a dish-shaped metal piece that is welded on the transmission-side of the carrier bearing, that will come into play later in the story.

I got the wire ran to the temperature sending unit. When I changed the intake for the quadrajet, I moved the sending unit to the head.

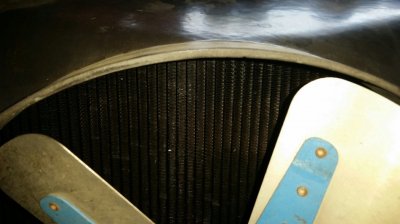

Now to change the alternator belt. The AC belt has to come off first and it wouldn't slide between the fan and shroud, so out with the battery, and off with the shroud. Now the alternator is replaced, and I noticed the charge wire is about to break. So I figure a new connector will fix that, yes and no. The nut was rusted to the stud and the stud wouldn't unscrew from the alternator. So instead of fighting any further I just replaced the alternator with the one from Mean Green. It is a high output type and it has a jumper wire from the positive post to the "F" terminal. Okay, what to do with the light blue wire that went to the "F" terminal, ah, just wrap it around and secure it on the loom until I can find out what it does. I was trying to be up to Mom and Pop's by 1 or 2. Got the alternator installed and all the the stuff bolted back in.

Now to check the timing. 8* BTDC. Not bad for doing it by ear, but 12* is better. I also found out I had the vacuum advance hooked up to the wrong port. Corrected that, and now the engine came to life. Adjusted the carburetor and decided to go get gas.

I pullout of the driveway and when I hit 2nd gear I hear a horrible sound coming from under the truck. I pulled over and looked it over. Couldn't see anything wrong. And then I remembered the metal dish by the carrier bearing. It was rubbing the bearing housing. CRAP! Of well, went and filled up and went back home. After a few more hours I got the transmission clean up and loaded in the truck, and then I crawled under to see if I could remedy the problem with the driveline. I was able to by lossening the bearing bolts and sliding it back a hair. No more grinding.

Called mom around 3pm to let her know I was leaving finally. So much getting up there by 2pm. So before I left town I see the temperature gauge is almost pegged to hot side. I asked myslef how could the engine run that much hotter now just because the sending unit is in the head and not the intake. I said screw it, I ran Mean Green hot like that and it never died so I took off up the canyon. When I shut it off up there it never boiled over and it didn't lose any coolant, so I have to chase down the sending unit wire and fix that.

One thing for sure, with the driveline being solid now, the truck drives a lot better. Not as hurky-jerky and it is way more responsive. And with the timing set to 12* and the vacuum advance on the correct port, the engine has way more power. It gets fairly decent mileage for having 4:57's in it. Should get even better with the OD engaged on the open road.