oneluckypops

Full Access Member

- Joined

- Feb 6, 2011

- Posts

- 2,210

- Reaction score

- 91

- Location

- Sedalia, Mo.

- First Name

- Luke

- Truck Year

- 85

- Truck Model

- K30 SRW

- Engine Size

- 5.7 Fuel injected Vortec/ 4L80E

Yep, or maybe see if I can find someone to make me the studs with a tab bigger knurl to it.

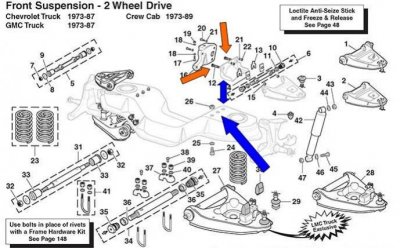

Sorry to say but as long as your truck has been like this your holes are gonna be egg shaped, Only way you could actually do any good is to go ahead and ream the holes out then make new studs to go in them but I would not knurl them I would just make them into bolts with a Wide flange for the inside of the frame and weld them inplace.