barrymattern

Junior Member

- Joined

- Aug 29, 2023

- Posts

- 14

- Reaction score

- 25

- Location

- Idaho

- First Name

- Barry

- Truck Year

- 1985

- Truck Model

- C10

- Engine Size

- 350

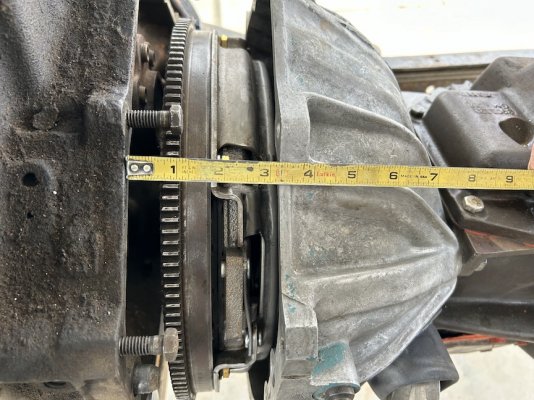

TL;DR: I'm in the middle of body swapping a 1985 C10 cab & bed onto a 1984 K20 frame. The frame was purchased without a front clip, engine, or doors so specific truck options are not known. After decoding the VIN I confirmed the donor truck/frame is a Canadian truck that had a 6.2L diesel, and after reviewing the 1984 GM Info Kit it appears to have had the C6P option. The issues started when we took the SBC 350 out of the 1985 C10 and placed it on the engine mounts of the 1984 frame in conjunction with the SM465/NP205 combo (the trans/tcase duo were purchased separately from either truck, and the exact years are not known). There is a near 3 3/4" gap between the back of the 350 & SM465 bell housing (see sbc350_sm465_gap.jpg). The trans crossmember is in the factory location with what appears to be the correct mounts – when comparing the 6.2L diesel engine mounts and SBC 350 engine mounts, they appeared to be the same so we used the 6.2 mounts in the location they were in. Are there any red flags as to why there would be such a large gap between the engine and transmission?

--------

For those interested in all the details...

After researching quite a bit here is what I've found out along with questions that have been raised in my mind:

- The bell housing part number on my SM465 is 460486 which appears to be used on various models from 1973-77. Trucks with the 6.2L in 1984 had a bell housing part number of 14061655. I can't seem to find a difference between the two as far as size (dimensions were hard to find) - does anyone know if the gap might be from that?

- My second thought was about the transmission crossmember. The crossmember that came with the SM465/NP205 duo had a smaller bolt-hole width on the sides that didn't fit the frame. I ended up buying a 1984 crossmember with the 4" bolt-hole spacing we needed (see crossmember_1984.jpg & np205_crossmember.jpg). The trans/tcase mounted well, and it went right onto the frame, so it seems to be a good fit, but not sure if that might be part of the problem?

- For now we've drilled new holes in the frame & moved the trans/tcase foward to mate to the engine. In doing so it seems to fit nicely as far as matching the factory position for the clutch bellcrank to the frame (see clutch_bellcrank.jpg). We're currently missing the clutch pivot ball seen missing in the pic, but we should have that soon. The pic is mainly to show that it looks like by moving the trans/tcase forward the 3 3/4" to fill the gap, it fits more in line with where it may need to be based on frame markers. But even still, it's odd we'd have to drill new holes for the trans crossmember.

- The next thing that is odd is that the VIN decodes the donor frame as a 1984 frame (see frame.jpg), but when comparing the frames in the CKRV Parts & Illustration Catalogs for the '84 & '85 years (2 separate catalogs), it looks like the frame is actually a 1985 based on looks alone? I found the plant sequential number on the top of the right frame rail and it matches exactly to the last plant sequential numbers of the VIN, which tells me that frame came with the cab sold as a 1984. Is it possible that it was manufactured late in '84 and left with early '85 parts? The glove box has a 1979 date on the bottom outside (even though the VIN sticker on the inside is 1984), and it looks like the date months that are scratched off on it are September thru December, which would fit the theory of the 1984 truck leaving the factory with early '85 parts. Just a thought...

--------

If you made it this far into the post, do you have any thoughts or info as to what we may have done wrong or ways we can move forward to get this build unstuck? On that note, let me also ask this – should this truck have a 2-piece rear driveshaft with a center support hanger/bearing, or should it be a 1-piece driveshaft going straight from the NP205 to rear differential? Any help is appreciated!

Thank you to anyone who made it to the end!

--------

For those interested in all the details...

After researching quite a bit here is what I've found out along with questions that have been raised in my mind:

- The bell housing part number on my SM465 is 460486 which appears to be used on various models from 1973-77. Trucks with the 6.2L in 1984 had a bell housing part number of 14061655. I can't seem to find a difference between the two as far as size (dimensions were hard to find) - does anyone know if the gap might be from that?

- My second thought was about the transmission crossmember. The crossmember that came with the SM465/NP205 duo had a smaller bolt-hole width on the sides that didn't fit the frame. I ended up buying a 1984 crossmember with the 4" bolt-hole spacing we needed (see crossmember_1984.jpg & np205_crossmember.jpg). The trans/tcase mounted well, and it went right onto the frame, so it seems to be a good fit, but not sure if that might be part of the problem?

- For now we've drilled new holes in the frame & moved the trans/tcase foward to mate to the engine. In doing so it seems to fit nicely as far as matching the factory position for the clutch bellcrank to the frame (see clutch_bellcrank.jpg). We're currently missing the clutch pivot ball seen missing in the pic, but we should have that soon. The pic is mainly to show that it looks like by moving the trans/tcase forward the 3 3/4" to fill the gap, it fits more in line with where it may need to be based on frame markers. But even still, it's odd we'd have to drill new holes for the trans crossmember.

- The next thing that is odd is that the VIN decodes the donor frame as a 1984 frame (see frame.jpg), but when comparing the frames in the CKRV Parts & Illustration Catalogs for the '84 & '85 years (2 separate catalogs), it looks like the frame is actually a 1985 based on looks alone? I found the plant sequential number on the top of the right frame rail and it matches exactly to the last plant sequential numbers of the VIN, which tells me that frame came with the cab sold as a 1984. Is it possible that it was manufactured late in '84 and left with early '85 parts? The glove box has a 1979 date on the bottom outside (even though the VIN sticker on the inside is 1984), and it looks like the date months that are scratched off on it are September thru December, which would fit the theory of the 1984 truck leaving the factory with early '85 parts. Just a thought...

--------

If you made it this far into the post, do you have any thoughts or info as to what we may have done wrong or ways we can move forward to get this build unstuck? On that note, let me also ask this – should this truck have a 2-piece rear driveshaft with a center support hanger/bearing, or should it be a 1-piece driveshaft going straight from the NP205 to rear differential? Any help is appreciated!

Thank you to anyone who made it to the end!