Yea, that's a terrible idea, and would never do that.

I really don't know how many amps that pump draws, but lets say for the sake of discussion that it's 5 amps, going to the one wire that powers the distributor. That one wire was never meant to power a motor, doing that is going to cause a voltage drop in the wiring to the distributor, so it's getting fed lower voltage than it should be.

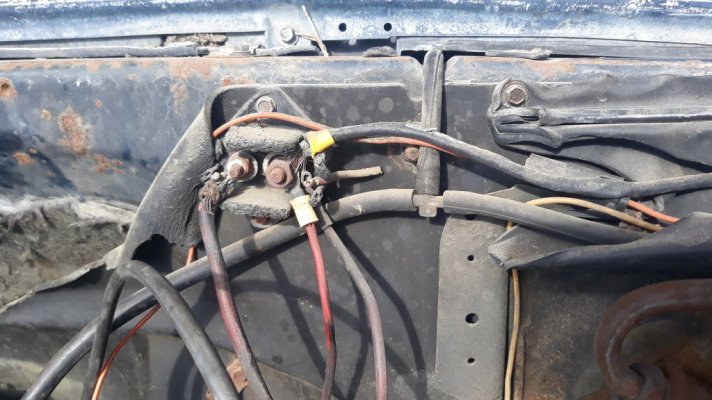

The best way to wire an electric pump would be though a relay, second best would be a key on power off the fuse box.

Also in the current set up not only is it likely that the distributor is getting less voltage than it should, it's very likely that the fuel pump is seeing reduced voltage. Lower voltage to a motor, increases amp draw, increases heat, and shortens the life of the fuel pump.

Ya, I'd say that really needs to be sorted out properly.

@jfrancom101 so if it was converted to a gas 350, you should be able to run a factory mechanical fuel pump. I'm sure there is no push rod under the pump plate in the motor, so you'd need to get one of those, plus a pump. Then depending on the pump you choose possible a regulator. If you decide to convert to mechanical pump we can talk more about the options then.