bluex

Full Access Member

- Joined

- May 9, 2013

- Posts

- 2,001

- Reaction score

- 2,678

- Location

- Spartanburg SC

- First Name

- Paul

- Truck Year

- 1978

- Truck Model

- C15

- Engine Size

- 350

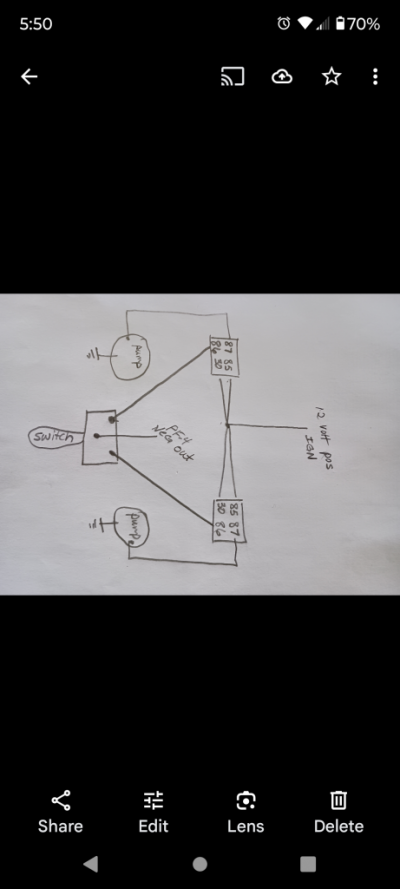

Great info Blue thank you, I opted for the PF4 XT recently that was not available at the time of my build that’s why my Sniper is in the classifieds, that said I do now need to run an external regulator and yes my truck is an 86 but did come with factory dual tanks… Perhaps AA has an 87 tank harness ? My head scratching is that wouldn’t the fuel pressure need to be regulated after the pumps but before the Pollak so the issue you had dosen’t occur ? The sniper is regulating fuel at the throttle body therefore the Pollak would be getting hit with full pump pressure is that not correct ?

System pressure is the same regardless of where it's regulated. Pressure is a measure of system restriction, yes the pump is capable of producing 100-110 psi if needed but if you just put a hose on it an let it pump into a bucket there's no pressure.

So wherever you regulate the pressure it'll be the same at the valve assembly. In general the return side is usually always less than 5 psi because that is after the regulator and the only restrictions are the hose itself and any bends or fittings.